#Structural Epoxy Applications

Explore tagged Tumblr posts

Text

L2 Certification Attempt

After obtaining my L1 attempt, I had originally planned to fly for an L2 attempt on the same rocket. However, I attended a VRA club night where a swap meet was being held and ended up with a Rocketry Warehouse (now Madcow) Broken Arrow 54. Sometimes a great deal is a great deal.

This was a pretty big step up from the cardboard and plywood construction I was used to, being entirely filament-wound fibreglass. Its large diameter/length ratio combined with its small split fins also made it intimidating. This kit is also intended only for dual-deploy, which is something I had never done before. I decided it was a good opportunity to challenge myself.

Build

The kit was pretty bare-bones, meaning I had to source a retainer and much of the hardware for it. I ordered a 38mm Aeropack retainer, and then I began the build.

The process was relatively simple, with through-the-wall fins like all my previous builds. However, this time they did not fit into divots in the centering rings, so I 3D printed a fin jig to hold them in place while the epoxy cured.

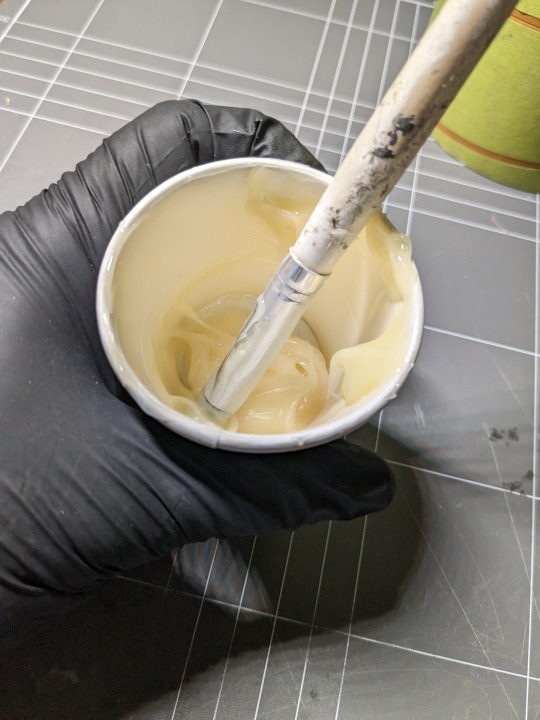

Speaking of epoxy, I moved away from the 5-minute Araldite I had used for previous builds in favour of a more serious adhesive. I used JB Weld for anything motor-adjacent because of its thermal tolerance, and Epiglue for all other structural attachments and fin fillets. This was recommended to me by a friend in Perth who flies truly ridiculous rockets and has used it on flights of up to Mach 2. It is also available from a local marine supplier, meaning I didn't have to pay through my nose to get hold of Rocketpoxy or West Systems. I was very pleased with how nicely it went on and how strong it was.

By this time I'd also nailed down my epoxy application and filleting methods - I use cheap silicone sculpting and grouting tools which can simply be cleaned with acetone after I'm done. For filleting, I also found that mixing the epoxy in a ziploc bag and piping it on like icing worked a treat.

My work gets cleaner with every set of fillets I lay down. These ones don't look fantastic, and the split fins were something I had never dealt with before, but that didn't matter for reasons that became apparent shortly after the epoxy had set.

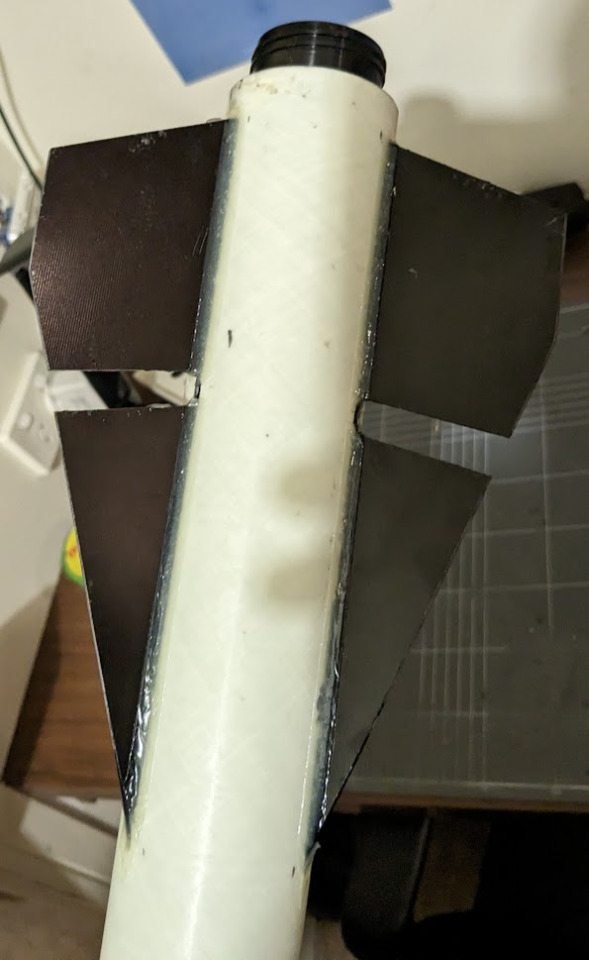

The morning after I applied these fillets, I got up to continue working on the rocket when I noticed that something had shifted overnight. The motor mount tube was somehow at an angle, as shown in the image above. I know I installed it perfectly level, but I didn't secure it while it set so I think it slipped as it cured. In my defense, I was quite sick and not firing on all cylinders when I had completed all the work up until now, but the realisation of what I'd managed to do was pretty disappointing and a bit of a knock to my confidence. Some measurements and a bit of trig suggested that the offset was only a degree or two, but the image suggests otherwise. I consulted some friends who are far more experienced flyers than I, and the consensus was a mix between 'send it' and Do Not Fly That Rocket, with more in favour of flying it than not. I looked at my OpenRocket sim for stability characteristics, and read some old Rocketry Forum posts about this model, all which pointed to it being rather squirrelly. In hindsight, I feel like I made the right decision, as I just couldn't ignore my gut feeling. I decided to rip it apart and rebuild it completely.

I did not take photos during this phase due to being completely covered with fibreglass dust, but I ended up using a diamond Dremel cutting wheel to first cut the fin can off, then cleanly slice the fins out of the body. I cannibalised a small section of the avionics bay tube to use as a coupler to reattach the aft section. I was then able to epoxy the whole thing back together, sand it all down, and it looked no different - apart from the motor mount being at the correct angle of zero degrees. I re-filleted the fins with a larger radius than before, as I wasn't happy with how they looked initially. I was very pleased with this effort, and confident to a) present this rocket to an RSO and b) fly it safely.

I also took the opportunity during this rebuild to modify the rocket to be motor-eject capable, by removing the bulkhead to which the recovery harnessing would be attached. I cut a small divot in the forward centering ring and attached a looped piece of kevlar around the motor tube before reinstalling it. This 'leash' provides the anchor point for a longer recovery harness to be attached to. I am very glad I did this, as not long after I was informed that my university club possessed a grand total of two (2) grams of black powder. Traditional dual-deploy would no longer be an option. More on that later.

To finish off the construction, I 3D printed rail guides from ABS and bolted them to the body, with a bit of JB Weld in there for good measure. I drilled pressure relief holes in the forward and aft sections of the body, and another in the avionics bay for altimeter readings. I then drilled a more smaller holes and installed screws to pin the nosecone to the forward section, and the forward section to the avionics bay. Since the flight would no longer be traditional dual-deploy, the rocket would not need to separate at these points. Finally, I gave it a purple paintjob and the name of CRUNCHWRAP 3.

At some point, Taco Bell might see these and send me a cease and desist. I am going to keep building and flying them until they do.

Recovery

With a proper dual-deploy ejection now out of the question, I turned to my backup plan. My team calls it the 'poor-man's dual deploy', even though it's arguably actually more expensive than using black powder. This involves deploying a drogue with the motor charge, then using a JollyLogic chute release device to deploy the main at whatever altitude you have chosen. There is a substantial risk of the harnessing becoming tangled using this method, but I didn't really have a choice. I used a 4.5m nylon shock cord, tied to the anchored kevlar leash. I divided the cord into thirds, tying a loop at each third. I attached the drogue to the forward-most loop, and the main to the aft loop. Both chutes were on quick links and swivels to reduce the risk of tangling as much as possible. Each of these chutes were wrapped in their own nomex protector, and then placed in the aft section of the rocket with their harness. I used a 36' (91-ish cm) main chute from Loc Precision, and a 40cm 4-gore drogue which I sewed using Scott Bryce's fantastic Spherical Parachute Pattern Generator.

Avionics

Although it ended up not being needed, I decided to send the flight computer I got hold of along for the ride. I thought it would be cool to get an altitude reading to compare with the simulated apogee. A buddy of mine in the US was getting rid of a few bits and pieces, so I bought his RRC2+ off him with the intent of flying it for my L2 attempt. First, though, it needed somewhere to live.

I found the supplied parts for the av-bay were a little lacking, so I added some modifications - the main one being drilled holes for two threaded rods to pass through. I used two for redundancy, since the idea of a single rod made me a little uneasy. I used wingnuts on these so I could fasten them nice and tight without the need for a spanner. It was also missing enough eye bolts, so I grabbed some from Bunnings.

I then designed and 3D printed a sled to fit onto the threaded rods and provide a mount for the battery and the flight computer. A very simple setup. The sled looks objectively awful since the printer was having a bit of a sook at the time, but the actual functionality was not affected and it serves its purpose just fine.

Motor

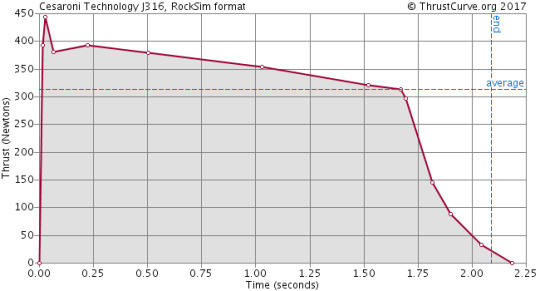

With an unbelievably limited amount of motors available in Australia at the time of writing, I had to work with what I could get hold of. I was lucky enough to snag was a CTI J-316 (pink!!) through my university team, which is a 38mm 5 grain reloadable motor with an adjustable delay of up to 17 seconds. Unfortunately, we didn't have a 5-grain case so I made do with a 6-grain case and a spacer. I only became aware of that the night before the launch, so I had to very quickly revise my recovery packing technique to account for the now limited real estate inside the body.

It provided an average thrust of roughly 316N, with a max of 450N, over a burn time of about 2.1sec, for a total impulse of roughly 650Ns. A pretty tame J motor, but still far more powerful than anything I'd ever flown before.

Simulation

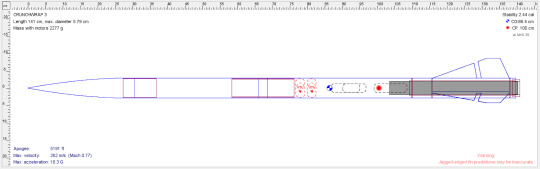

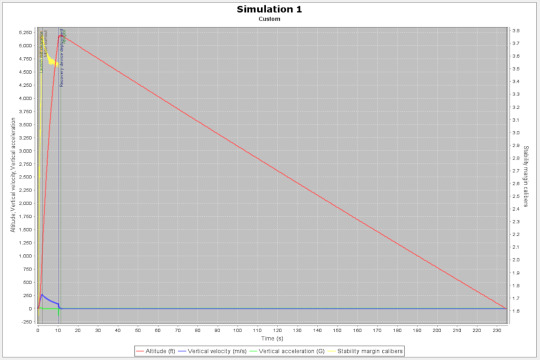

After carefully weighing every single component of the rocket and entering them into OpenRocket, I simulated the flight on the motor above. The entire vehicle weighed 2.7kg, with a length of 1.41m. It was simulated to hit Mach 0.77, and fly to an apogee of 5191ft.

Theoretically, the centre of pressure and centre of gravity would be 0.86m and 1m respectively from the tip of the nose cone. This would give a stability calibre of 2.44 at Mach 0.3 - however, this rocket is quite a bit faster than that. Also, the 'rule of thumb' which says a rocket's CG should be roughly 1.5 body diameters in front of the CP is not as helpful on rockets with a length/diameter ratio of over 10, such as this one (which is 24). Here, the CG should be roughly 10% of the overall length in front of the CP, which it was, almost (9.6%). The stability calibre off the rod was predicted to be only a little over 1.5 (6%), but given that it would be going 31m/s I was confident this would be fine as long as it didn't launch into a strong wind gust. At motor burnout, stability would be up near 3.8 (15%), which I was happy with.

I set the motor delay to the full 17 seconds for the simulations, as anything shorter would have the recovery devices deployed before apogee. This would a) cut the flight short and more importantly b) place a huge amount of strain on the harnessing and chutes due to a very high deployment speed. With the full delay, deployment would be at 11.3m/s, which the harness and drogue could handle easily. Ground hit was simulated to be a brisk but not destructive 6.8m/s.

As an aside, OpenRocket includes a little disclaimer about 'jagged edge fin predictions may not be accurate'. I bore this in mind through the whole process, but based on others I'd seen fly and forum posts I'd read online, I was comfortable with what I was doing.

Flight

L2 certifications require passing a written exam with two sections - technical knowledge and the Tripoli safety code. I had already passed the exam (100%, don't mind if I do) at a previous date, so all I had to do was install my motor, altimeter, and recovery gear. I didn't even have to drill out a delay. After a quick field CG test and a visit to the RSO tent, I was ready to rack up.

A few new recruits to our team came out to the launch day, so I enjoyed an opportunity to show them how to set up for flight, install an igniter, and test for continuity.

After a small delay to clear the range and ensure the skies were clear overhead, the LCO hit the button.

The rocket flew straight and fast on a frankly gorgeous purple flame, and almost instantly got high enough that we struggled to keep a visual on it. A puff of smoke indicated the ejection charge had blown, and then I was able to see the fluoro yellow gores of the drogue as it opened. The rocket began to drift slowly as it came down, as there was a fairly stiff breeze blowing at the time. I had programmed my chute release to 500ft, and it performed as intended. The main chute deployed and thankfully none of the recovery gear got tangled. I watched it gently descend, albeit with a decent drift going on, and set itself down in a field about 800m away. After a gentle stroll (read: powerwalk to warm up, it was freezing), we arrived at the rocket. It had been dragged a little and the chute had become tangled on the ground, but all was intact. One quick pitstop at the RSO tent later, I had my L2!

Upon reflection....

Things to improve

Use a much smaller drogue. The one I flew was about twice as big as it needed to be, and it was far too windy for such a chute. I simply didn't have a smaller one, although making one would have only taken about an hour.

I didn't get any useful readings from my altimeter. I don't believe I set it up properly, so I need to make sure I learn to do that and fly it as a passenger on at least one more flight before I use it as a deployment computer. I am disappointed that I couldn't get a figure to compare with the simulation.

Use a proper stand to rest the rocket on, perfectly horizontally, during construction. This would have avoided the whole debacle of the motor mount slipping and me consequentially having to rip it apart and rebuild.

Things that went well:

Being absolutely prepared and packing my car the night before, and bringing spares of most components, made launch prep a breeze

That was the first flight of my homemade drogue, and upon inspection afterwards there was no damage. I can now be confident that others of the same design and similar construction that I have planned for bigger rockets will perform in a similar way.

The recovery technique worked as intended, with no tangling. This is probably not a viable option for rockets going any higher, but it's nice to have in the back pocket for projects of this scale if black powder and/or avionics access might be an issue

I am also extremely relieved that this certification only took me one shot, rather than the three that my L1 took. I think it reflects well on my progress.

Next:

Fly it again with proper dual deploy, if I can get my hands on some black powder

Scratch build of a rocket of similar scale

...... L3?

2 notes

·

View notes

Text

Epoxy Grouting & Regrouting: The Ultimate Solution for Waterproofing

Are you tired of constantly dealing with leaking showers, cracked grout lines, and permanently stained surfaces? It's time to switch to epoxy grouting and regrouting in Singapore! This innovative product is the pinnacle of all grouts and is perfect for both commercial and residential surfaces.

In this blog, we'll discuss everything you need to know about epoxy grouting, its benefits, and areas where it can be applied.

What is Epoxy Grouting?

Epoxy grout is a more advanced product than traditional grout, and it requires a bit more effort and skill to use effectively. It's made up of two parts, a resin, and a hardener, that must be mixed together thoroughly before application.

The product dries up faster than standard grout, so it must be applied quickly. It's essential to remove any residue within 20 minutes of application, and excess grout will be repeatedly washed away with a cleaning solution.

Benefits of Epoxy Grout:

It does not stain

It is protected against chemicals

It is 100% non-porous

It lasts a lifetime

It can be used on floors and walls

It does not require sealing

It comes in a large range of colors to match your tiles

Areas for Epoxy Grouting and Regrouting:

Bathrooms: Epoxy grouting is perfect for bathrooms as it prevents water from penetrating into the walls and floors, which can lead to mold growth and structural damage.

Showers: Showers are constantly exposed to water, making them prone to leaks and other waterproofing issues. Epoxy grouting can effectively seal off shower walls and floors, preventing any water damage.

Floors in common areas: Common areas such as lobbies, corridors, and hallways are high-traffic areas that require durable and long-lasting waterproofing solutions. Epoxy grouting is a great option for these areas.

Kitchen splashback tiles: Kitchens are also prone to water damage due to the presence of sinks and other water sources. Epoxy grouting can prevent water from seeping into the walls and floors, protecting your kitchen from water damage.

Balconies and garage floors: Balconies and garage floors are exposed to the elements, making them more susceptible to water damage. Epoxy grouting can protect these surfaces and ensure that they last longer.

Pavers and patio areas: Pavers and patio areas are also prone to water damage due to rain and other weather conditions. Epoxy grouting can help prevent water damage and keep these areas looking great for longer.

Pool surroundings: Pool areas are constantly exposed to water, making them prone to leaks and water damage. Epoxy grouting can effectively seal off the pool area and prevent any water damage.

All wall areas internal and external: Epoxy grouting can be used to waterproof both internal and external walls, protecting them from water damage and ensuring that they last longer.

Common Reasons for Regrouting:

Leaking showers

Cracked grout lines

Leaking balcony floors

Missing grout lines

Permanently stained grout lines

Efflorescence deposits

The choice to change the color of the grout

Crumbling grout lines

We provide a range of waterproofing contractor services, from remedial rectifications and repairs to brand-new builds. We are experts in installing waterproofing membrane systems in Singapore and impart technical knowledge throughout your project.

Our services come with upfront pricing guarantees, 24/7 emergency service, licensed and insured work, no callout fees, customer satisfaction, and on-time service.

To Summarize:

If you're looking for a long-lasting and reliable solution for waterproofing, epoxy grouting and regrouting in Singapore is the answer. It's a more advanced product than traditional grout and requires more effort and skill to use effectively.

The benefits of using epoxy grout are numerous, and it can be applied to a wide range of areas. If you're looking to get started on your project, don't hesitate to contact us today!

2 notes

·

View notes

Photo

Kodiak F1

The Kodiak F1 made its debut at the 1983 Frankfurt Motor Show. It was produced by Speed & Sport GmbH. of Stuttgart Germany, under the leadership of Mladen Mitrović. Speed and Sport manufactured convertible roofs and other automotive accessories, and Mitrović wanted to fulfill his ambitions to build a bespoke super car. With the help of the University of Munich, and some pioneering CAD software, Mitrovic carried out the car's development in record time.The F1 was a coupe with gullwing doors that resembled the Mercedes-Benz C 111 experimental concept car. The body consisted of Kevlar and carbon fiber reinforced plastic. Underneath this bodywork was a tubular steel chassis, to which the body and chassis tub were bonded using epoxy. Light weight and structural rigidity were the main goals guiding its design.

Though the initial prototype was shown with an AMG tuned, 6.0 liter V8 boasting 380bhp, other options were made available to potential customers including a stock Mercedes Benz V8, as well as a blueprinted Chevrolet 350ci V8, carrying aluminum Brodix heads and a quartet of Webers' or Bosch fuel injection for roughly 320-340 horsepower. In all applications power was put to the road via a 5-speed ZF gearbox.

Rounding out the package, mechanically, were a suspension consisting of unequal length A-Arms, Koni shock absorbers, and Brembo brakes. The empty weight was given as 1,000 kg and the acceleration from zero to 200 kmph was less than ten seconds. Certainly brisk for the time...

With many components cribbed from the Mercedes parts bin, the cars interior had a familiar appearance. Kodiak F1 was equipped with Air conditioning, a 300 Watt audio system with 22 speakers, leather seats, and a MOMO Leather steering wheel from Italy. Every inch covered in leather, it certainly looked the part of a luxury GT.

28 notes

·

View notes

Text

Research allows for 3D printing of 'organic electronics'

An example of 3D laser printing. Credit: University of Houston

When looking at the future of production of micro-scale organic electronics, Mohammad Reza Abidian—associate professor of Biomedical Engineering at the University of Houston Cullen College of Engineering—sees their potential for use in flexible electronics and bioelectronics, via multiphoton 3D printers.

The newest paper from his research group examines the possibility of that technology. “Multiphoton Lithography of Organic Semiconductor Devices for 3D Printing of Flexible Electronic Circuits, Biosensors, and Bioelectronics” was published online in Advanced Materials.

Over the past few years, 3D printing of electronics have become a promising technology due to their potential applications in emerging fields such as nanoelectronics and nanophotonics. Among 3D microfabrication technologies, multiphoton lithography (MPL) is considered the state-of-the-art amongst the microfabrication methods with true 3D fabrication capability, excellent level of spatial and temporal control, and the versatility of photosensitive materials mostly composed of acrylate-based polymers/monomers or epoxy-based photoresists.

“In this paper we introduced a new photosensitive resin doped with an organic semiconductor material (OS) to fabricate highly conductive 3D microstructures with high-quality structural features via MPL process,” Abidian said.

They showed that the fabrication process could be performed on glass and flexible substrate poly(dimethylsilosane). They demonstrated that loading as low as 0.5 wt% OS into the resin remarkably increased electrical conductivity of printed organic semiconductor composite polymer over 10 orders of magnitude.

“The excellent electrical conductivity can be attributed to presence of OS in the cross-linked polymer chains, providing both ionic and electronic conduction pathways along the polymer chains,” Abidian said.

To demonstrate the potential electronic applications based on the OS composite resin, his team fabricated various microelectronic devices, including micro-printed circuit board, which comprises various electrical elements, and an array of microcapacitors.

Three dimensional bioprinting of organic semiconductor microdevices based on MPL has potential in biomedical applications including tissue engineering, bioelectronics and biosensors. Abidian’s team successfully incorporated bioactive molecules such as laminin and glucose oxidase into the OS composite microstructures (OSCMs). To confirm that the bioactivity of laminin was retained throughout the entire MPL process, primary mouse endothelial cells were cultured on OS composite microstructures. Cells seeded on laminin incorporated OSCMs displayed evidence of adherence to substrate, proliferation, and enhanced survival.

“We also assessed the biocompatibility of the OS composite structures by culturing lymphocytes, namely splenic T-cells and B-cells, on the fabricated surfaces and compared them with control surfaces. After seven days of culture, OS composite polymers did not induce cell mortality with approximately 94 percent cell viability compared to the control surfaces,” Abidian said. “In addition, the potential effect of OS composite polymers on cell activation was also studied. After seven days of culture, there was no significant difference in the expression of activation markers on the lymphocytes between OS composite structures and control surfaces.”

Finally, Abidian proposed a maskless method based on MPL for fabrication of bioelectronics and biosensors. They fabricated a glucose biosensor similar to Michigan style neural electrodes. Glucose oxidase, an enzyme for the specific recognition of glucose, was encapsulated within the solidified OS composite microelectrodes via the MPL process. The biosensor offered a highly sensitive glucose sensing platform with nearly 10-fold higher sensitivity compared to previous glucose biosensors. In addition, this biosensor exhibited excellent specificity and high reproducibility.

“We anticipate that the presented MPL-compatible OS composite resins will pave the path towards production of soft, bioactive, and conductive microstructures for various applications in the emerging fields of flexible bioelectronics, biosensors, nanoelectronics, organ-on-chips, and immune cell therapies.” Abidian said.

Researchers use organic semiconductor nanotubes to create new electrochemical actuator

More information: Omid Dadras‐Toussi et al, Multiphoton Lithography of Organic Semiconductor Devices for 3D Printing of Flexible Electronic Circuits, Biosensors, and Bioelectronics, Advanced Materials (2022). DOI: 10.1002/adma.202200512

Provided by University of Houston

Citation: Research allows for 3D printing of ‘organic electronics’ (2022, June 24) retrieved 26 June 2022 from https://techxplore.com/news/2022-06-3d-electronics.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no part may be reproduced without the written permission. The content is provided for information purposes only.

New post published on: https://livescience.tech/2022/06/26/research-allows-for-3d-printing-of-organic-electronics/

2 notes

·

View notes

Text

Composite Materials in Railways

Introduction to composites and FRPs

For a composite material to be considered a real composite, it must have two components whose combined strength is greater than that of the sum of their individual components. 1+1 doesn't equal 2 in the world of composites. A composite material can take several forms, such as particleboard, for example (wood and glue).

Figure: FRP Composites

A resin and a structural fiber are the two main components of FRP composite materials. FRP composites employ a wide range of fiber reinforcements. Composites manufacturers have traditionally relied on low-cost glass fiber (fiberglass) as their primary material. The great tensile strength of aramid fiber, such as that found in DuPont's Kevlar trademarked product, makes it excellent for ballistic and impact applications. Its high modulus-to-weight ratio makes it possible to create lightweight and strong structures with carbon fiber, another common reinforcing fiber.

Although various fibers, such as basalt, thermoplastic fibers, natural fibers, and others, are routinely utilized in composites nowadays. They are glass, aramid (a polyamide), and carbon (a carbon-based polymer).

Purely in terms of fibers, they're supple and pliable. Textile weaving and knitting machines, both traditional and updated, are used to weave or sew these fibers together into cloth. To create a strong composite material, these cloths must be saturated with resins before being used.

Composites are the intended use for the resins. Most resins used in composites are either brittle or overly flexible when used on their own. Thermoset or thermoplastic are the two main types of resins. Composite resins have traditionally been thermoset, although thermoplastic resins are becoming more prevalent.

Polyester, vinyl ester, urethane and phenolic are just a few of the thermoset resins available. There is a chemical reaction that completely links the molecules of these resins before they solidify. The resin will wet out the structural fibers in composites, encasing and curing them.

Curing takes place in a mould, mandrel, or die, giving the completed composite the desired shape and appearance. Even a flat sheet of paper might be used to make it. Once the composite has been cured, the resin and fiber can be selected to produce qualities that are customized to the application's specific needs.

Possible Properties of FRP Composites

· Lightweight

· Noncorrosive

· Fire and flame resistance

· Toughness / Impact resistance

· Tailored flex properties

· Attractive Cosmetics

· Non-conductive or extremely conductive

· Water resistance

All across the world, composites have been hailed as a wonder material for the transportation industry. Beyond the benefits of their different mechanical features, composites give train coaches an attractive appearance, particularly when there are few joints, and the material is molded. Assimilability for modular panel type construction adds to the components' maintainability. Due to their non-recyclability, composite materials offer a distinct advantage over metals when it comes to railways in India.

Increasingly, composite materials are being used in the railway industry, where the performance gains can be substantial. Up to 50 percent for structural and 75 percent for non-structural applications bring associated benefits of high-speed, decreased power consumption and lower inertia, as well as the capacity to carry bigger payloads. Structural materials with high rigidity minimize (even eliminate) supporting framework, enhance passenger space, and readily carry fittings. Composites are easy to handle and install, and their modular design allows for quick installation. The system as a whole is protected from fire thanks to its fire-resistant properties.

Passenger coaches rely heavily on composites because of their superior structural qualities and improved looks. Glass fiber reinforced with polyesters/epoxies and phenolic resins is the most common material used in the construction of coaches. The Indian Railways have already started implementing plans to use composite materials, particularly in the cars' seating areas. Higher speeds can only be achieved with lighter coaches in a mass transit system. Until recently, steel and cast iron were replaced by stainless steel and light alloys in the construction of railroad car bodies. GFRP, which resists corrosion and is easy to work with, is becoming more and more common.

The Indian Railways have already identified composites as a promising material for use in their equipment. Composites are being introduced into numerous railway applications by the Research, Designs, and Standards Organization (RDSO) and Integral Coach Factory (ICF). Several carriage components, such as louvre and glass shutters, window sills and frames, toilets, coach interior panels, brake pads, and battery box trays, have already been well developed in FRP composite.

The trains utilize natural fiber thermoset composites for a variety of applications, including the 1.6 mm-thick roof ceilings and floors. The railroads' goal is to completely eliminate the use of wood and plywood in the carriages. In addition to the above, the Indian Railways has started using composites in the following applications: components for coaches like window frames & shutters; a wall protector in toilets; axle box covers for coaches – the latter of which is made of composites; and modular interior panel and partition; luggage bins, toilet modules, bulkheads, interior walls & doors; interior furnishing and seating; and engine room sound attenuation.

An additional number of components will be replaced with composites by the RDSO in the near future. In addition to the FRP gear case for locomotives (a weight savings of 372 kg per six-axle system), axle box covers, brake-gear bushings, berth and chair backings, roof water tanks, lavatory chutes, window guides, doors (main entrance, sliding door for first class AC compartment, inter-communication door in AC coaches), folding tables, fuel injection pump cover, luggage racks, etc.,

Figure: Lightweight composites for railway

As per the ICF General Manager Sudhanshu Mani, “The interiors of the Train 18, developed indigenously by the Integral Coach Factory (ICF) have been made up of composite materials, which are fire resistant,”

The next step in the project's evolution will be the production of FRP sliding doors for carriage restrooms. It has been possible to make two alternative doors, one with a 'compreg' interior and FRP skins on both sides, and the other sandwich structure with FRP external skins and PU foam in the middle. The results of RRL-extensive Bhopal's testing were quite favourable.

The use of composites is likely to increase dramatically with the introduction of new coaches on the Indian Railways, and local suppliers will have high expectations for components with the highest possible quality. When it comes to bringing in cutting-edge composite fabrication technology and experience to the United States, this is an urgent need.

The development of innovative thermoset and thermoplastic composite goods would go a long way in generating new application areas and therefore extending its market reach. India can surely carve out a role in the upcoming technology of composite fabrication with its great knowledge base in diverse resins, catalysts, and curing systems, as well as its ample supply of various raw materials. Because the composites industry relies heavily on human labour, having enough highly trained workers available in the country would be an asset to its growth.

2 notes

·

View notes

Text

Cabinet Making CNC Machine/ CNC Kitchen Cabinet Wooden Door

The cabinet making cnc machine is our newly-developed CNC Router with combined function of material loading and unloading for cabinet-making, widely used in home decoration, shop and office furniture. It is equipped with Italy HSD Spindle, Italy Boring unit and advanced Syntec control system, Japanese Yaskawa servo and Taiwan reducers.

Custom and general Cabinet Making Machineis one of the most popular applications for CNC routers. IGOLDENCNC CNC routers have brought industry standards to a new level with our quality and components, delivering what you would find in much higher-priced CNC routers at a cost competitive with the less industrial designs.

📷

Features of Cabinet Making Machine:

* Square tube lathe bed with more solid structure and strong stability because of low center of gravity.

• Vacuum table in 4zones can fix materials of different sizes effectively.

• Taiwan TBI balls screws, HIWIN square guide rails, high precision, large load bearing and stable running.

• Gantry-travelling, sturdy, reliable and stable, non-deforming, high locating accuracy.

• Mach3 control system, with computer controlled, very stable.

• Unique ability to save several point of origin on several workpieces.

• No engraving saw-tooth, smooth undersurface, legible contour, by high-power spindle.

• Auto seeking original point system, a good way to improve the working effeciency.

• Large compatibility of drawing software, such as Type3, artcam and some other CAD or CAM.

Cabinet Making Machine application:

* Furniture: wooden doors, cabinets, plate, office and wood furniture, tables, chair, doors and windows.

* The wood products: voice box, game cabinets, computer tables, sewing machines table, instruments.

* Plate processing: insulation part, plastic chemical components, PCB, inner body of car, bowling tracks, stairs, anti-Bate board, epoxy resin, ABS, PP, PE, PEHD and other carbon mixed compounds.

* Decorate industry: Acrylic, PVC,MDF, artificial stone, organic glass, plastic and soft metals such as copper, aluminum plate engraving and milling process.

Model

1325 CNC Nesting Machine

Working area

1300*2500mm

Spindle

ATC 9KW HQD air cooling spindle

Inverter

Fuling

Motor

Dorna servo motors

Driver

Dorna servo driver

Control System

Taiwan LNC control system

Table

Double layer Vacuum table + position cylinder + secondary dust collection + Pusher system

Oil lubrication

Automatic lubrication

Limit

Omron limit

Transmission

XY axis Taiwan helical rack Z axis Taiwan ball screw

Rail

X,Y,Z axis Germany Square guide rail

Screw

Z axis TBI ball screw

Bed

Thick steel welded big square tube

Gangry

Strong frame

Pillars

Steel pillar(Suitable for high-end customers)

Cabinet

Independent cabinet

Voltage

3 phase/380V

Color

As requirement

Tools

1 box(10 pieces)

Company Information

Jinan iGolden CNC Equipment Co.,Ltd. is a R&D,manufacturing,sales integration company that specializing in router cnc, laser engraving and cutting machine, plasma cutting machine, cutting plotter,etc.The main configuration all adopt top parts which imported from Italy, Japan,Germany, etc.We adopt international advanced producing technologies to improve our products.Our products are widely used in advertising,woodworking, artworks, model, electric, CAD/CAM Industry Model, Clothing, Package Printing, Marking, Laser Sealing and so on.And welcome to visit us for more choices.

2 notes

·

View notes

Text

Attributes of Fiberglass Over Precious metal

Fiberglass Multiaxial - Attributes of Fiberglass Over Precious metal

Fiberglass is among the strongest and nearly all durable materials utilized in construction today. Fiberglass is comprised of numerous microscopic grains which have been bonded together under ruthless and heat. When the fiberglass fibers are exposed to pressure and heat, they become gentle and elastic. This allows the individual grains to stick together like glue when the material is located or molded. In a very multiaxial frame, a thick part of fiberglass is combined with epoxy or other resin to provide mechanical strength and also durability.

Fiberglass includes excellent chemical and physical properties, making it ideal for numerous applications. From their ability to conduct electricity to it has the strength and battle to corrosion, fiberglass plays a major role in the mechanical design of many structures. Unfortunately, the material also results in significant drawbacks of which limit its usefulness in certain applications. A multiaxial frame made from fiberglass is typically too brittle to use in preference to concrete in structures that need to withstand heavy a good deal.

A second prevalent drawback of implementing fiberglass in multiaxial eyeglass frames is that it is not flexible at many. Unlike other elements, fiberglass is struggle to conform to improvements in direction. Should the structure in question has to be moved in a continuing state of motions, such as lifting a plane, it may prove extremely problematic. Even if the actual multiaxial structure should be slightly bent, the sheer amount of energy required to accomplish so causes your whole structure to sag and buckle under strain.

A final drawback of using fiberglass with multiaxial designs usually its low hardware strength limits as much force that could be applied to this structure. Fiberglass frames are typically not designed to look at even the a lot of extreme stresses subjected to them. This stiffness also helps it be difficult to realize design goals, like having the multiaxial structure move in certain ways. So as to overcome these weaknesses, designers often use steel for a structural base for that multiaxial structure. Steel's strength and durability allow it to become the perfect groundwork.

Steel's strength, as well as the material's all round stability, ensures the fact that structure can endure the stresses located upon it. This stability is essential in ensuring that the structure remains structurally noise while remaining rather unaltered. Steel's load-bearing characteristics will also be important when building a structure because of the building's structural condition is directly plagued by how well it can resist forces of all kinds. The number 1 consideration is the integrity of the structure's columns. Steel's tensile strength is first rate; it is literally impossible for virtually any structure to failure under the weight belonging to the structure's columns. This reliability makes steel remains a great value material for multiaxial structures eventually.

In addition to be able to strength, Woven Roving Suppliers another consideration with regard to structural reliability is a multiaxial's strength aspect. This term refers to the quantity of force a construction can withstand just before it buckles. Fiberglass, unlike steel, is not considered to obtain a strength factor. Although some engineers look at the lack of structural shear in the form of liability, other engineers view the lack of shear as a strength enhancer.

1 note

·

View note

Photo

3D nano-inks push industry boundaries

A new, 3D-printable polymer nanocomposite ink has incredible properties—and many applications in aerospace, medicine and electronics.

Mechanical engineering researchers at Michigan Technological University have created a way to make a 3D-printable nanocomposite polymeric ink that uses carbon nanotubes (CNTs)—known for their high tensile strength and lightness. This revolutionary ink could replace epoxies—and understanding why its properties are so fantastic is a first step toward its mass use.

3D printing, also known as additive manufacturing, is more versatile and efficient than casting. It adds a material with precision, often in complex geometries, with considerably less excess to cut away. Adding low-dimensional nanomaterials such as CNTs, graphene, metal nanoparticles and quantum dots allows 3D-printed materials to adapt to external stimuli, giving them features such as electrical and thermal conductance, magnetism and electrochemical storage.

But 3D printing using plastic, metal or something else entirely isn't new. What Tech researchers have done differently is use polymer nanocomposites (made of epoxy, carbon nanotubes and nano-clay) and a printing process that doesn't sacrifice functionality. The junction of material type and morphology—size, shape, structure—in polymer nanocomposite inks is the ultimate in form meeting function.

Read more.

#Materials Science#Science#3D printing#Ink#Polymers#Nanocomposites#Nanotechnology#Composites#Carbon nanotubes#Nanotubes#Carbon#Additive manufacturing#Michigan Technological University

35 notes

·

View notes

Text

Types of Welded Wire Mesh & Specifications

Wire mesh reinforcement is widely used as an important element for construction for industrial as well as commercial applications. Wire Mesh is an integral part of construction and is widely preferred as an important tool for construction purposes. After years of research and development and exposure to client’s requirements across the world, we can now manufacture and deal in the following types of Welded Wire Mesh.

For more inv=fo visit our Website : http://www.almiqathardware.com/

The technique and process of welding determine which type of welded wire mesh is suitable for a particular job and which can be used accurately. Below is a list of different types of Welded Wire Mesh that we can supply:

1. Epoxy Coated Welded Wire Mesh

Protection from corrosion is the most important reason to choose this type of Welded Wire Mesh. By applying a protective coating on the surface of the mesh, the metal part in the inner surface can be protected from corrosion. Besides this, Epoxy Coated Welded Wire Mesh also adds color. This aspect of this mesh is very common in applications such as zoos, farming, decorations, etc. Epoxy Coated Welded Wire Mesh usually carries lower costs as the inner metal wire is of less thickness.

For more inv=fo visit our Website : http://www.almiqathardware.com/ 2. Galvanized Welded Wire Mesh Galvanization is a process that involves the use of zinc for the coating of a surface. We can manufacture Galvanized Welded Mesh using two distinct processes: electro process and hot-dipped process. While the former makes for a glossy surface, the latter results in a matt finish. Hot Dipped Welded Wire Mesh carries more costs than the former owing to superior characteristics to avoid corrosion. For general application, Electro Galvanized Welded Wire Mesh is preferred. 3. Stainless Steel Welded Wire Mesh The welded wire mesh made of Stainless Steel consists of a uniform steel barrier at the intersections. Multiple grades of Stainless Steel Welded Wire Mesh can be produced, most common being 304, 316, 316L. Owing to its ease of use and high reliability, this type of wire mesh is most preferred in critical industries such as Oil & Gas, FMCG, Desalination plants, etc. Costs for this type of Wire Mesh are usually high due to its superior anti-corrosion properties. 4. Welded Wire Fencing Welded Wire Fencing is manufactured in rolls or panels. These pre-constructed fences are available with or without galvanization. Fence without galvanization is usually low-cost and easy to install. Rolls are customized to the client’s specifications, need minimal to no cutting, and can easily be installed by skilled labor. There are a lot of additional materials like posts, rings, pliers, etc which are needed to install a fence. Panels are pre-constructed in set shapes and sizes to fit the structure it is being used. It can be dismantled and reused easily. This type of fence is most commonly used in roads for walkways, residential complexes, sports fields. For more inv=fo visit our Website : http://www.almiqathardware.com/

1 note

·

View note

Text

FRP Tank Market Size, Growth, Strategic Trends and Forecast to 2027

The research report "Global FRP Tank Market: By Fibre Reinforcement (Glass fibre and Carbon fibre), By Material Type (Polyester, Epoxy, Vinyl esters and others), By Application (Water & Waste Water, Pulp & Paper, Chemicals, Oil & gas, Power), End User (Aerospace, Construction, Transportation, Others) and Geography -Global/Region/Country Forecast to 2027", The Global FRP Tank Market was valued at US$ 2.08 Billion in the year 2020 and anticipated to grow USD 3.34 Billion by 2027 at CAGR of 7% over the forecast period 2021-2027.

Glance our 200 slides market research and competitive intelligence research report, 25 Tables and 65 Figures and other qualitative sections with an in-depth TOC on "Global FRP Tank Market: By Fibre Reinforcement (Glass fibre and Carbon fibre), By Material Type (Polyester, Epoxy, Vinyl esters and others), By Application (Water & Waste Water, Pulp & Paper, Chemicals, Oil & gas, Power), End User (Aerospace, Construction, Transportation, Others) and Geography - Global/Region/Country Forecast to 2027".

View detailed Report Description at https://precisionbusinessinsights.com/market-reports/global-frp-tank-market/

Growing demand for FRP tanks from water treatment plants and chemical industries to drive the market

FRP is a modern composite material utilized to construct chemical plant equipment like vessels and tanks. This material is leaf proof. FRP makes use of two basic laminate types such as a structural laminate and a corrosion barrier. FRP tanks are the vessels made using fiberglass-reinforced plastic. FRP tank market will experience considerable CAGR during the forecast period owing to the factors such as increasing chemical industries, oil and gas industries and waste water treatment plants. In addition, FRP tanks have several crucial benefits to provide such as easy maintenance, light weight and high physical strength. Another leading factor boosting the Global FRP Tank Market over the forecast time frame is the wide range of applications of FRP tanks in various industries to store chemicals or any other corrosive material. But, the high price of composites and lack of awareness about product can hinder the FRP tank market growth

There is growing awareness among people about water pollution as well as water management across the globe hence, a number of projects related to this began by the governments from different countries and started using FRP tanks for storing waste water. Furthermore, the wide use of FRP tanks in paper and pulp industry is also projected to drive the market growth over the forecast period 2021-2027.

Impact of COVID-19 FRP Tank Market: In addition, the report discusses the implications of COVID-19, including the industry's initial response and strategies for ensuring business continuity in the coming years. Asia-Pacific Dominating the Global FRP Tank Market among Other Regions

Asia Pacific became the larger market revenue share obtainer in the market witnessing considerable CAGR. There are a number of factors that accelerate the market growth in this region such as growing count of desalinations plants, increasing replacement of old existing tanks, looming freshwater shortage, increasing demand from retail fuel stations, conservation of rainwater, huge demand for energy and growing demand for non-corrosive and lightweight storage tanks from industries like power, chemical and water & waste water industries. FRP tank market in North America is anticipated to witness considerable rate due to the presence of chemical industries in the region.

Request a case study or sample research report at https://precisionbusinessinsights.com/request-sample?product_id=36172

Competitive Assessment:

There are a number of prominent industry players working in the Global FRP Tank Market and some of them are ZCL Composites (Canada), Enduro Composites (U.S.), LF Manufacturing (U.S.), Edwards Fiberglass (U.S), Denali Inc. (U.S.), EPP Composites (India), Hexagon Composite Engineering Sdn Bhd (Malaysia), Composite Technology Development, Inc. (U.S.), Luxfer Group (U.K.) and Hexagon Composites ASA (Norway).

About Precision Business Insights:

We are a market research company that strives to provide the highest quality market research insights. Our diverse market research experts are enthusiastic about market research and therefore produce high-quality research reports. We have over 500 clients with whom we have a good business partnership and capacity to provide in-depth research analysis for more than 30 countries. In addition to deliver more than 150 custom solutions, we already have accounts with the top five medical device manufacturers.

Precision Business Insights offers a variety of cost-effective and customized research services to meet particular research requirements. We are a leading research service provider because of our extensive database built by our experts and the services we provide.

Contact Us:

Mr. Satya

Precision Business InsightsTM | Toll Free: +1 866 598 1553

Email: [email protected] Kemp House, 152 – 160 City Road, London EC1V 2NX Web: https://precisionbusinessinsights.com/ | D U N S® Number: 852781747

1 note

·

View note

Photo

Why Concrete Repair Is Important And What Is The Best Concrete Patching Materials?

Concrete Repair can be a costly proposition for any building owner. Concrete is also one of the most robust and most utilized materials in the entire world. Structures built with concrete possess several benefits, from superior fire protection to environmental advantages. However, it is also very sturdy and solid, yes, but certainly not a super-substances.

Due to the properties mentioned above, concrete Repair has the potential to become a very costly affair. In such cases, the use of high-performance cement used in repairing substantially increases the repair costs. As we all know, cracks are ugly, especially if they appear in areas where people spend a lot of time and effort. So how do we remedy such a situation? In simple words, we use high-performance cement to patch cracks in concrete.

The most popular method of Concrete Repair Raleigh NC, repairing small cracks in concrete structures, is to use crack reinforcement. The process makes attempts of water seepage into concrete. Over time, water becomes a latent vapor due to expansion and contraction in the area of application. Such cracks act as an invitation for corrosion.

Once the water seeps in, it combines with other soil particles and forms pitting or cracking. The cracking motion of the compound causes the pitting to widen. This action propagates itself through the mixture to adjoining cracks. Thus, Repair becomes a lot easier, faster, and less expensive. You can also choose to use an electro-mechanical bond-forming machine to form the Repair.

Another standard repair procedure that is done is epoxy floor repairs. Epoxy, a thermosetting polymer, is used to add water resistance to concrete floors. The advantage of using epoxy is that you need not wait for concrete to cure. The curing process can take time, and concrete heals faster than epoxy. It also adds longevity to the concrete. Epoxy does not deteriorate as the years pass by, and it can be left untreated for more extended periods.

Concrete repairs can also be made at home. If you want to try your hand at doing such maintenance at your home, you need to understand the cracking process first. This will help you avoid unnecessary mistakes. Cracks occur when there is insufficient expansion or contraction of the concrete structure. To get the best possible crack repair, you need to add water to the trial while still fresh.

Another type of Repair is coarse aggregate floor repairs. Crawl spaces are formed because of insufficient fine aggregate, compacted soil, and water. Fine aggregate, compacted soil, and water are the main reason why the surface of concrete slabs becomes cracked. To make such characters look fine again, you need to apply some topical or internal Repair. The most common topical repairs include concrete sealers, sanding, sealing, and painting.

The last major structural repairs in which concrete floors are involved are those that are caused by fatigue. When there is excessive pressure on the foot caused by people's weight and other heavy items, the floors are damaged. The key to such floors repair is to add more reinforcing bars to the affected area. The most common materials that are used in reinforcing our steel rebar, stamped steel, concrete toppings, and interlocking carpet boards.

Apart from these, concrete surfaces crack due to varying environmental conditions. For example, a poorly maintained road may give way to cracks. Similarly, standing water on the ground, uneven or sloping floor, exposure to heat, chemicals, and vibration can crack concrete surfaces. It is essential to add a special sealant to prevent the water from contacting the concrete in such cases.

Furthermore, when concrete begins to crack, it is best to remove the broken pieces before they start to weaken. This is because wasted concrete details tend to spread bacteria and mold spores. This will result in a risk of developing diseases like botulism and anthrax. Moreover, such a contaminated area will also not be suitable for anyone to live in. You need to add special care when working on cracked concrete; otherwise, you will end up spending more time and money trying to remedy the situation.

Lastly, if you have a damaged concrete structure, you should get it repaired as soon as possible. This is because repairing damaged concrete structures is costly and poses a greater risk of spreading mold spores than undamaged ones. This is because such materials are damp and more likely to contain high moisture concentrations than dry ones. Therefore, it is best to get professional help from an experienced contractor when repairing a damaged area. Otherwise, you may end up spending more on unnecessary damages.

1 note

·

View note

Text

7 Trends You May Have Missed About Stamped Concrete

Skim coat/broom complete concrete resurfacing – Restore and protect harmed, pitted, flaking and stained concrete back on the seem of a whole new concrete surface.

Well being — decorative concrete is a wonderful substitute to carpeting for folks struggling from respiratory ailments and allergy symptoms.

Present substrate redecorating and renovating – Alter the appearance of existing concrete or Wooden substrates by way of implementing "thin stamped" or "thin stained" overlays, developing new textures, hues and designs. For use on professional or resident pool deck, this commonly requires the shape of "splatter textures" or "knockdowns," wherein polymer cement is placed on the prevailing concrete substrate inside a moderately textured complete (regular of one/8” thickness) in various designs.

Usually do not use on vertical surfaces or locations matter to hydrostatic tension. NOT for industrial use or places subject to forklifts. Surfaces could develop into slippery when soaked. Use warning when going for walks on surface area when moisture is existing.

Stacked 2’x2’x6′ decorative blocks Not just do decorative concrete blocks supply a similar protection in managing traffic as a normal concrete block, but their decorative structure also provides a valuable aesthetic reward.

decorative concrete block for the foundation. Concrete block was also utilized for garages. The auto was considered a hearth hazard so folks felt safer with their vehicles in a fireplace evidence concrete block garage.

Thoroughly clean all applications and equipment with clear drinking water. For disposal of vacant containers and unused product or service, contact your domestic refuse selection support.

Colored concrete can be obtained from several Prepared mix concrete providers and a lot of have color charts out there. Acid staining[edit]

Considering that 1990 in Arizona. We satisfaction ourselves inside the set up of the greatest hunting, routine maintenance free of charge, straightforward to clean flooring coatings & painting providers!

Decorative flooring is a big expense, so the standard of the products that you are specifying as well as popularity from the contractor are important considerations. Based on the Tile Roofing Institute, there are many factors to recollect When selecting an installation contractor:

Use in 4’ x 4’ sections. Begin with the roller in the center from the section and roll outwards in random Instructions. Avoid frequent patterns and knock down challenging edges using the roller.

An write-up with the time mentions the fact that it took so long because they experienced for making the concrete blocks on internet site, and wait for them to heal. The Rectory upcoming doorway can be product of decorative concrete blocks. We now have several residences inside our downtown region also created solely of decorative concrete blocks.

The benefits of the dry-shake technique include improved finishability, a limiteless range of colors, and a tough, abrasion resistant surface. Reactive and passive stains help the transformation of concrete into an enduring get the job done of art. The mottled, variegated, and practical look produced by staining present concrete is commonly quite possibly the most appealing feature of the decorative ground. When handled using a stain, no two flooring are alike. Most stains is often applied to new or old, simple or colored concrete surfaces.

Given that fantastic detail could become better, many thanks to numerous decorative concrete solutions available today, such as concrete stamping, stains, spray knockdown finish, epoxy flooring, and polyurea polyaspartic coating.Allow me to share the top household floors which will take pleasure in these:

1 note

·

View note

Text

12 unique advantages of LED lighting

Energy Conservation and sustainable development is no longer a selective issue, but it is the only way of world’s future development. Led as the representative of the new light source lighting to replace the traditional light source, it is causing a great change in lighting industry. Driven by innovative technology, the new lighting products are constantly being updated, from incandescent lamps to energy-saving lamps, halogen lamps to LED lamps. The lighting products have achieved energy-saving upgrades, and at the same time, they have also been improved in comfort, the lighting effect is also more diverse. As the representative of the Green energy-saving light source, LED lighting has become the most potential market in the industry. Compared with the more mature light source, what are the leading advantages of LED? The following is a brief introduction by the author.

12 unique advantages of LED lighting

In 1923, the scientist O.W. Lossew discovered that the P-N junction of silicon carbide had unidirectional conductivity and luminescence; around 1955, R. J. Haynes presented a study on P-N junction of semiconductor germanium, G. A. Wolff studied the luminescence of Gallium Phosphide; in 1968, the first red LED was produced by Monsanto and HP in the United States, making it an electronic product.

(1) energy conservation: the spectrum of leds is almost entirely concentrated in the visible light band, with a luminous efficiency of 80 to 90 per cent. The results show that the

luminous efficiency of the ordinary incandescent lamp is 12 lm/w, the life is less than 2000 hours, and the luminous efficiency of the spiral fluorescent lamp is 60 LM/W, with a life span of less than 8,000 hours, the T5 fluorescent lamp has a 96 ALMW life span of about 10,000 hours, while the 5 mm diameter white LED has a life span of 20 something 28 LLMW and can last more than 100000 hours. Some also predict an infinite upper limit on the lifetime of future leds.

The conventional wisdom is that cfls can save up to four fifths of energy, but leds can save up to a quarter more than cfls, a far greater innovation for Solid State Lighting. In addition, LED also has other advantages, high-quality light, basically no radiation, is a typical green lighting source, reliable and durable, very low maintenance costs, and so on. Because LED has the above other solid light source is unable to match the characteristics, 10 years later LED lighting industry will be the mainstream light source.

(2) safety and Environmental Protection: LED working voltage is low, mostly 1.4 something 3v; ordinary LED working current is only 10mA, ultra-high brightness is only 1a. Led in the production process do not add “Mercury” , do not need to inflate, do not need glass shell, impact resistance is good, earthquake resistance is good, not broken, easy to transport, very environmental protection, known as “Green Energy” .

(3) Long Life: LED small size, light weight, shell for epoxy packaging, not only to protect the internal chip, but also has the ability to light transmission and spotlight. Leds typically have a lifespan of between 50,000 and 100,000 hours, and because leds are semiconductor device, even frequent switches don’t affect their lifespan. At present, incandescent lamps, fluorescent lamps and energy-saving fluorescent lamps are mainly used for household lighting.

(4) Fast Response: the response frequency τmc of leds is related to the lifetime τmc of a few carriers injected. For example, for leds made of GaAs material, the response frequency of τmc is about 16 something 160 mhz in the range of 1 something 10 ns, this high response rate is sufficient for displaying a 6.5 mhz video signal, which is one of the key factors in achieving a video LED large screen.

At present, the lowest LED response time has reached 1 microsecond, the general for a few milliseconds, about the common light source response time 1/100. Therefore, it can be used in many high-frequency environments, such as car brake lights or state lights, can shorten the braking time of the vehicle behind the car, thus improving safety.

LED light source powerful advantage

(5) High luminous efficiency: incandescent lamps and halogen lamps have a luminous efficiency of 12-24 LM/W (Lumen/w) , fluorescent lamps have a luminous efficiency of 50 Something 70 lm/w, sodium lamps have a luminous efficiency of 90 Something 140 LM/w, and most electricity consumption becomes heat loss. The light efficiency of LED can reach 50 Something 200 LM/W after improvement, and the light has good monochromatic, narrow spectrum, no filtering can be directly issued colored visible light.

(6) small size of LED components: more convenient for the layout and design of various equipment, and can better realize the effect of “see the light but not the light source” in night scene lighting.

(7) high concentration of LED light energy: concentrated in the smaller wavelength window, high purity.

(8) LED light directivity is strong: brightness attenuation is much lower than traditional light source.

(9) LED can be driven by low-voltage DC power: with the advantages of small load, weak interference, the use of lower environmental requirements.

(10) Better control of the composition of the Luminescence Spectrum: This makes it suitable for local or focal lighting in museums and exhibition halls.

(11) The size of the semiconductor luminescent layer and the List of semiconductor materials forbidden band can be controlled: thereby emitting light of various colors and having a higher degree of color.

(12) High color rendering: will not cause harm to the human eye.

In conclusion: as an emerging technology sector, the light-emitting diode industry is still in a fast developing stage, and we are pleased with the progress of Science and Technology, but we also have to realize that both the technology sector and the regulation of the industry, compared with the traditional light source, they are not mature and sound. There is still a long way to go before the LED can truly replace the traditional light source. We believe that by promoting the healthy and orderly development of the entire industry, continuously accelerating the pace of application and gradually transforming the traditional industry, and promoting the adjustment of the industrial structure, it will open energy-saving green quality of life for people.

Sousce by: https://www.recolux.cn/12-unique-advantages-of-led-lighting/

1 note

·

View note

Photo

Using bioinspired microvasculature to control material properties

Researchers have created and demonstrated a new vascular metamaterial that can be reconfigured to modify its thermal and electromagnetic properties.

"We drew inspiration from the network of tiny vessels found in living organisms and have incorporated such microvasculature into a structural epoxy reinforced with glass fibers—essentially vascularized fiberglass," says Jason Patrick, corresponding author of the research paper.

"And we can control multiple characteristics of the composite material by pumping different fluids through that vasculature. This reconfigurability is appealing for applications ranging from aircraft to buildings to microprocessors." Patrick is an assistant professor of civil, construction and environmental engineering at North Carolina State University.

The metamaterial is made using 3D printing technologies. This allows engineers to create networks of tiny tubes, known as microvasculature, in a wide variety of shapes and sizes. The microvasculature can be incorporated into a range of structural composites, from fiberglass to carbon fiber to other high-strength materials for body armor.

Read more.

#Materials Science#Science#Metamaterials#Biomimicry#Glass fiber#Glass fiber reinforced plastic#Epoxy#3D printing#North Carolina State University

37 notes

·

View notes